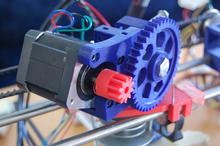

Hobbed Bolt

By Ben Nitkin on

Wow. It's been a while since I worked on this. In fact, the whole thing's a bit dusty. I'll give it a good cleaning before I start printing.

Towards the end of last summer, I realized that the old hobbed bolt - the thing that drives filament into the hot end - had worn out. Hobbing is threading on the bolt that grabs the filament and drives it into the hot end. The printer doesn't print so well when it can't push filament.

Recently, I bought another hobbed bolt, and it just arrived!

When I went to swap it in, I found the hobbing (notches) were in the wrong place, and ran to the engineering building for some spacers.

Next problem: with the spacers in place, the gearbox doesn't line up anymore. The big gear stands off too far from the drive gear. So, I popped off the stepper motor and pried at the gear with a screwdriver. (Fun fact: the right tools make anything easier. I don't have the right tools.)

Now to power it up! Steppers - check. USB - check. Power - check. Power supply online. Serial connection up. Temperature probes working. And the Z axis takes a dive.

Not working yet, but it's still alive. Cool.

The X axis is fine, as is Y. Z needed to be plugged back in; one of the connectors had worked loose. And with that, the printer was back. Time to figure out the hot end!

I took apart the hot end, which had fallen apart in transit from home to school, then reassembled it. I also put stronger springs into the cold end - should provide more driving force.

Problem, though. The pocket holes for nuts in the cold end are smaller than the nuts themselves. I guess the saying's true: when all you have is a dremel, everything looks like it needs a good grinding.

So, I ground the holes bigger. What can I say - it worked!

The hot end, cold end, and axes are all together. Time for some testing. And then, god willing, extrusion!